Students and Faculty Honored with SARA National Design Awards for Design-Build Project and Applied Research

Assistant Professors of Architecture Katie MacDonald and Kyle Schumann, who also direct the Before Building Laboratory and are co-founders of After Architecture, have received multiple Society of American Registered Architects (SARA) Awards as part of this year's national awards program, established to recognize excellence, creativity, and innovation in architecture and design projects. These awards celebrate projects that push creative boundaries and adhere to principles of sustainability, functionality, and aesthetics.

MacDonald and Schumann were recognized for their outstanding applied design research projects: Sylvan Scrapple and Four by Four by Zero Waste, in the categories of Material Sciences, and Related Arts, respectively.

Schumann's spring 2025 advanced research studio titled Timber Topographies, which was supported by the ACSA/SLB Timber Education Prize, also received an Honor Award in the Student Category for an innovative design-build project sited at Morven, a 2,913-acre living laboratory where sustainability research, teaching, and practice converge for the University of Virginia community.

MacDonald and Schumann, along with two students from the Timber Topographies studio — Harris Agnew (BSArch '25) and Isaac Goodin (MArch '25) — attended the awards gala for the SARA National Awards which took place at the National Building Museum in Washington, D.C., in November.

The School of Architecture congratulates MacDonald, Schumann, and their students on these accolades and the accomplishment of these innovative projects and studio pedagogy. Below, we share excerpts of the design research team’s description of each acknowledged project to offer a closer look at the ideas and details behind this celebrated work.

Timber Topographies

A real-world design-build project developed as part of an advanced design research studio, Timber Topographies develops architectural potentials for timber beyond the planar assumptions of standardized lumber. Constructed for the UVA Sustainability Lab at Morven, sited in the Virginia piedmont, the project takes shape as a meandering screen and bench, with angles in plan to orient views toward the surrounding topography and in elevation to merge with the mountains beyond. Non-planar timber systems are deployed in service of program: a place for rest, shade, and orientation to the site.

Two novel timber systems are constructed with campus waste logs using a faculty-invented robotic sawmill developed by the Before Building Laboratory: a porous wavy wall made of beetle-kill ash notched onto juniper ground beams and an undulating bench made of white pine. The bench geometry is designed for comfort and to rotate one’s body toward friends in conversation. To aid in eventual decommissioning, no adhesives are used, connections are screwed, and all timber is left untreated.

Project Credits

Instructor

Kyle Schumann, Assistant Professor of Architecture

Students

Harris Agnew (BSArch.’25)

Shiza Chaudhary (MArch.’25)

Mary Cotterman (MLA’25)

Meredith DeLong-Maxey (BSArch.’25)

Mairead Driscoll (BSArch.’25)

Manuel Estrada (MArch.’25)

Isaac Goodin (MArch.’25)

Darien Hersh (MArch.’25)

Connie Liou (MLA’25)

Zeya Min-Fink (BSArch.’25)

Amanda Nordwall (BSArch.’25)

Atlee Paterno (MArch.’25)

Elizabeth Solkey (MArch.’25)

Madeleine Zahn (MArch.’25)

Material Sourcing & Project Support

UVA Sawmilling & UVA FabLab

Robotic Sawmill

Invented by UVA faculty Kyle Schumann, Katie MacDonald & Gavin Garner (U.S. Full Patent Application No. 19/221.934)

Funding

Studio and project funded by the 2024 Timber Education Prize from the Association of Collegiate Schools of Architecture (ACSA) & Softwood Lumber Board (SLB)

Sylvan Scrapple

Sylvan Scrapple, a public installation commissioned for Exhibit Columbus 2023: Public by Design, is a wooded oasis formed by a 110-foot-long snaking wall. The public space design demonstrates new possibilities in robotic manufacturing, mass timber construction, and material reuse.

Non-linear wood unfit for traditional lumber is used to construct curving panels. Boards cut on a purpose-built robotic sawmill are stacked into snaking walls, making use of natural curvature to create thin structural surfaces. Straight boards are salvaged from a demolished building, refinished, and assembled into straight panels linked the curved segments. The curved and straight panels are all post-tensioned with threaded rod, avoiding the need for adhesives during assembly and allowing for easy decommissioning into boards.

Reusing materials local to Columbus, bricks salvaged from the burned Irwin Block and renovated First Christian Church tower are collected in custom welded gabion cages. Gabions double as pieces of urban furniture, such as wall, dining table, coffee table, and stairs.

Wood, bricks, and scraps form a 15’ long dining table that creates a center for the installation. Bound with bioresin, this table closely resembles congealed scrapple. A game of “I spy” uncovers panels salvaged from Eliel Saarinen’s church tower and branches from Mill Race Park. The public space was exhibited from August - November, 2023.

Project Credits

Project Leads

Katie MacDonald, Co-director of Before Building Laboratory and Co-founder, After Architecture

Kyle Schumann, Co-director of Before Building Laboratory and Co-founder, After Architecture

Project Team

Shiza Chaudhary

Ammon Embleton

Isaac Goodin

Emily Ploppert

Margaret Saunders

Material Donation

UVA Sawmilling

Irwin Block

First Christian Church

Photography

Leonid Furmansky

Hadley Fruits

After Architecture

Funding

Exhibit Columbus University Design Research Fellowship

UVA Jefferson Trust Annual Cycle Grant

UVA School of Architecture Summer Research Grant

UVA Vice Provost for the Arts Grant

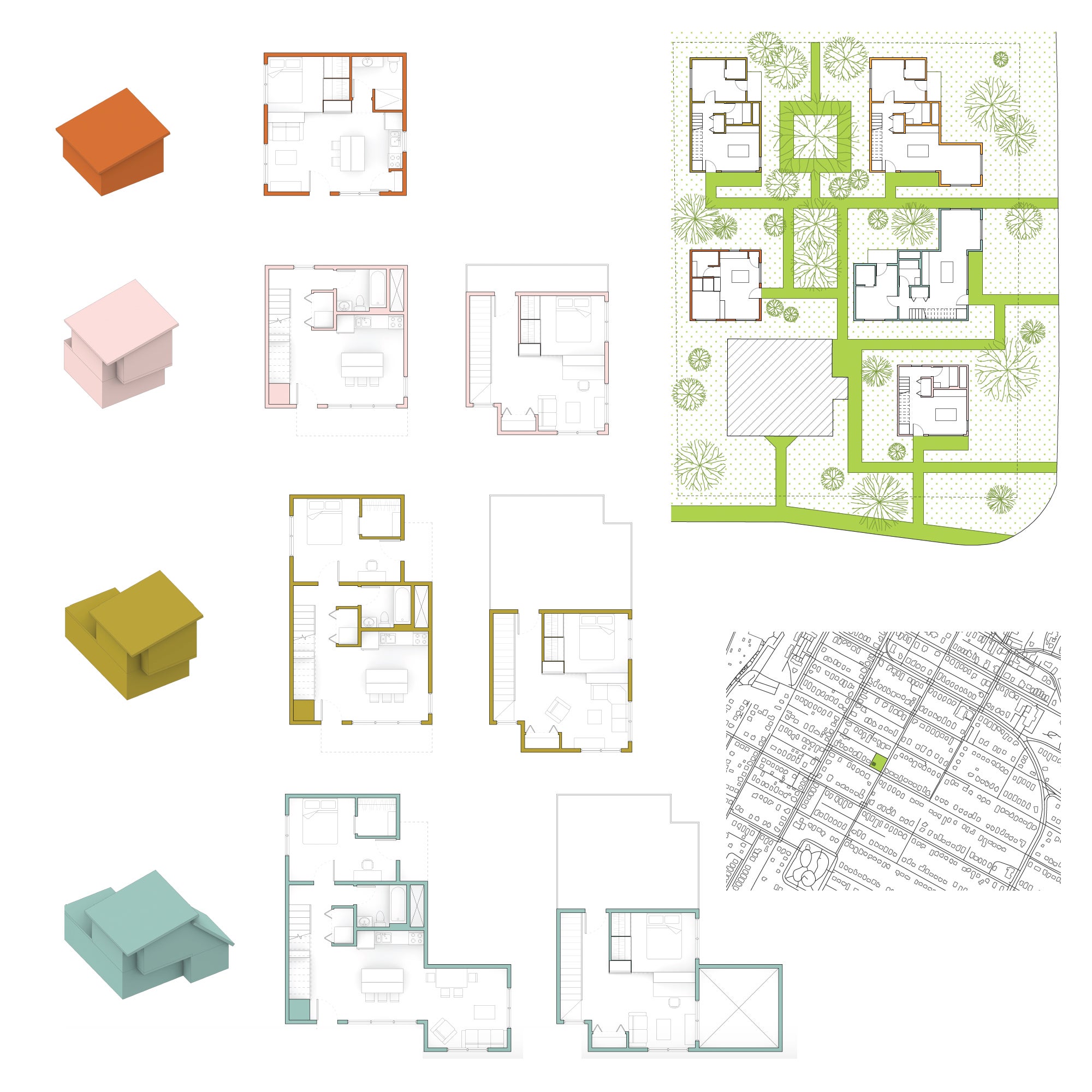

Four by Four by Zero Waste

An exercise in minimal fabrication and material economy but maximum material expression, the pair of column lights is produced from a standard Douglas fir 4x4. A series of simple operations produces a set of parts that aggregate into a pair of separate but related elements. Three cross cuts produce four 2’ lengths, followed by a single smooth curve cut by bandsaw into two perpendicular faces of each 2’ length. The resulting parts are flipped, inverted, and aggregated into column-like forms that are solid at the top and bottom with a central void.

Typical methods for producing curving wood architectural elements include steam bending boards, glulam, and profiling then laminating curves out of plywood sheets, all of which result in significant material waste, embodied energy, time, and cost, including considerable investments in custom molds, clamping mechanisms, manufacturing precision, and specialized fabrication environments. On the other hand, the low-tech, undulating curve cuts made on a traditional woodworking bandsaw in this project result in two usable halves and expressive wood grain.

Four by Four by Zero Waste explores the expressive potential of wood. Undulating cuts along the board’s short axes move like a wave through the board, resulting in a unique grain patterning that resists traditional grain readings. The lexicon of plain, rift, and quarter-sawn expands to a new grain language in which the curving form cut in the material intersects with the curves of the tree’s growth rings, producing a dance of grain in three dimensions.

Project Credits

Project Leads

Katie MacDonald, Co-director of Before Building Laboratory and Co-founder, After Architecture

Kyle Schumann, Co-director of Before Building Laboratory and Co-founder, After Architecture